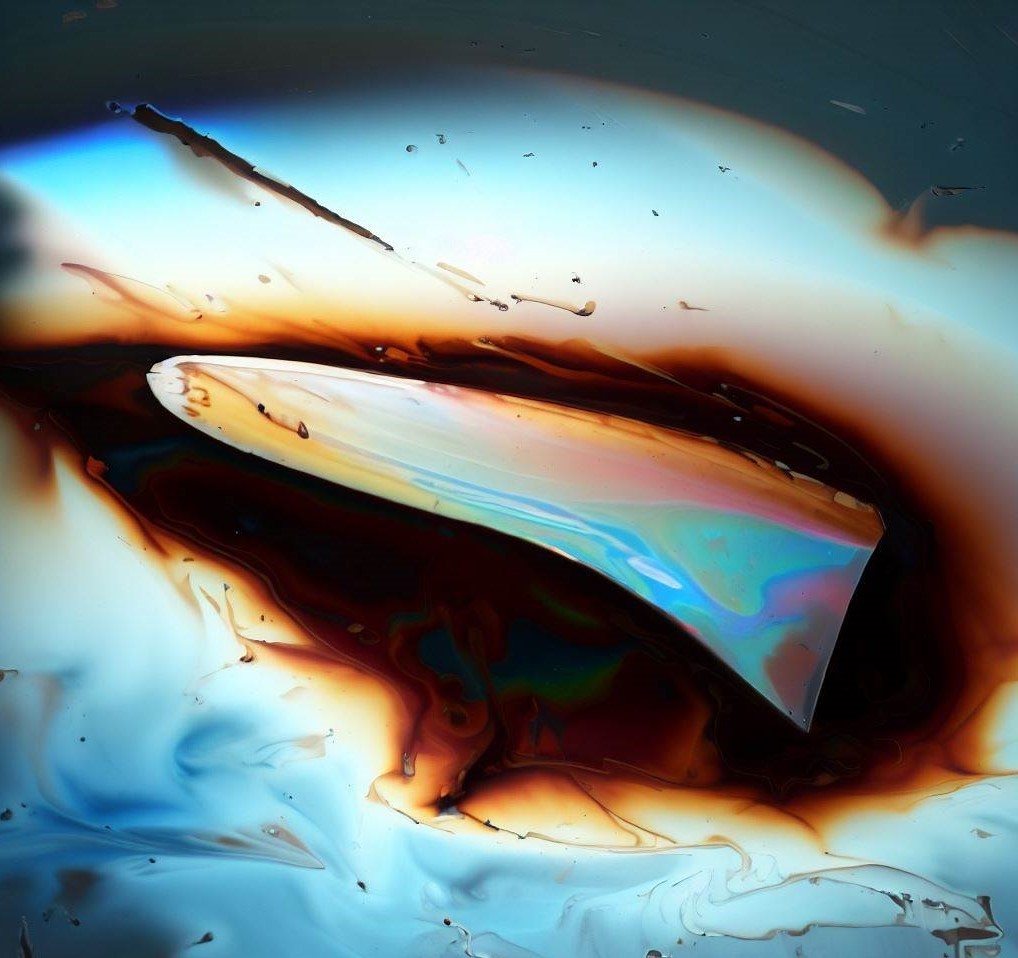

Wind energy has significant growth potential and applicability on a global scale. Europe, China, and offshore wind turbines set new records in 2020, installing over 93 GW for a total of 742.7 GW. Approximately 2.4% of wind turbine blades must be decommissioned annually in Europe, but wind turbine blades are rarely recycled due to their complex composition. The blade is usually made of carbon fiber, glass fiber and epoxy resin. There is a method by using a small molecule-assisted technique dissolving waste composite materials containing ester groups (connecting part of polymers) and recycle wind turbine blades. This method requires temperatures below 200 °C and can achieve up to 100% resin degradation yield. (1)

The recycling process can be applied to composite materials such as wind turbine blades and carbon fiber composites. The solution is made of ethylene glycol (EG) and organic solvent to clearve the ester bonds in the polymer. This cleavage enables the separation and recovery of the carbon and glass fibers, as well as the epoxy resin, from the waste composite materials. The solution used for the recycling process (solvolysis) can be reused multiple times, creating a closed loop for this type of material. The recycling process involved the solvolysis of glass, carbon fiber, and epoxy resin oligomers. The method allows carbon and glass fibers to be recovered with greater efficiency and without additional degradation. The experiment has been successfully scaled up to a 2 liter scale below 200 degC, and can be applied many different types of polymers including esters.

(1) Sci Rep 13, 9270 (2023). https://doi.org/10.1038/s41598-023-36183-4

Leave a comment