Photoelectrochemical (PEC) water splitting is a promising method for sustainable hydrogen production. High-efficiency photoanodes are crucial for achieving high solar-to-hydrogen conversion efficiency. Organometal halide perovskites (OHPs), which is well known as a promising photovoltaic material, have been highlighted as potential materials for high-efficiency PEC water splitting. In the photovoltaic application, photo-excited charge carriers are extracted to generate electricity, while they are used for chemical reactions, oxidation and reduction of water in photoelectrochemical water splitting. In the PEC application, OHPs are combined with a catalysed surface for water oxidation or reduction to utilise the generated charge carriers.

The strategy for improving material properties is exactly the same for both solar cell and water splitting applications. To reduce undesired losses of photogenerated carriers limit the efficiency, and defect-passivated electron transport layers effectively suppress the non-radiative recombination of photogenerated carriers. High-quality electron transport layers are crucial for reducing internal losses in OHP-based photoanodes. In the case of water splitting reaction, catalyst with high activity promotes the reaction kinetics of PEC water oxidation. Integration of OHP photoanodes with catalyst-integrated encapsulation layers mitigates external losses. The researchers focused on suppressing undesired losses in organometal halide perovskite-based photoanodes for efficient photoelectrochemical water splitting. They achieved this by optimizing the electronic band alignment and improving the charge carrier dynamics, and implement strategies included surface passivation, interface engineering, and optimized material compositions.

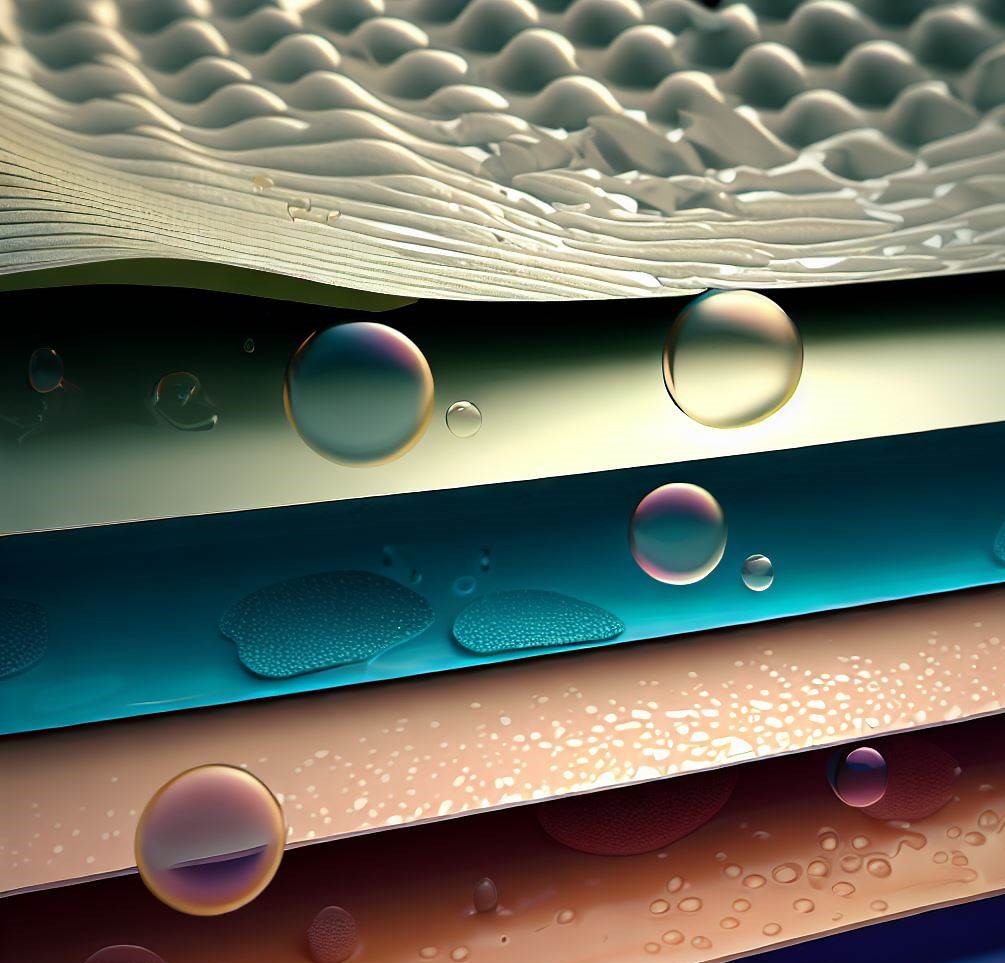

In a recent paper published in Advanced Energy Materials,(1) the fabricated Fe-doped NiS/Ni foil/OHP photoanodes exhibit a remarkable applied bias photon-to-current efficiency (PCE) of 12.79%. This is the highest applied bias PCE reported for OHP-based photoanodes, demonstrating the suppression of undesired losses. Defect-passivated electron transport layers and catalyst-integrated encapsulation layers are key strategies. The development of OHP photoelectrodes with high PEC performance is enabled by suppressing undesired losses. OHP PV cells were encapsulated by Fe-doped NiS/Ni foils to protect the OHP photoanodes from water molecules and promote the reaction kinetics of PEC water oxidation. The encapsulation layers and OHP PV cells were electrically connected by solid fusible metal (FM) pieces. Fabrication of Fe-doped NiS/Ni foil/OHP photoanodes using solution process enabled cost-effective and low-temperature production.

N-i-p structured OHP PV cells based on (FAPbI)(MAPbBr) were used for the fabrication of the OHP photoanodes. (N-i-p refers to the perovskite solar cells with an n-type/insulator/p-type order of the conducting layer.) Bilayer-type SnO layers were formed as electron transport layers (ETLs) on fluorine-doped tin oxide (FTO) substrates. Defects at the interface between the OHP layers and SnO ETLs were effectively passivated through GTMACl treatments. GTMACl was introduced as a passivating molecule at the interface between the SnO ETLs and OHP layers. GTMACl effectively enhanced the hole-blocking ability of SnO ETLs and prolonged the carrier lifetime by suppressing non-radiative recombination. GTMACl-treated OHP PV cells exhibited higher power conversion efficiency (PCE), higher short-circuit current density (J), and higher fill factor (FF) compared to untreated cells.

(1) J. Seo, S. Lee, et al., Advanced Energy Materials, https://doi.org/10.1002/aenm.202300951

Leave a comment